pvc ceiling panels

Links

- The integration of fiberglass in the manufacture of food grade equipment has revolutionized the food processing industry. Renowned for its durability and non-corrosive properties, fiberglass is increasingly becoming the go-to material for a wide range of equipment used in the food sector. This article delves into the significance and applications of fiberglass food grade equipment, highlighting its advantages and the myriad uses it serves.

Water and Wastewater Treatment: Used in water and wastewater treatment facilities due to its corrosion resistance and slip resistance. NSF-61-certified materials permit use in drinking water facilities.

fiberglass water tank. Their non-porous surface prevents algae growth, reducing the need for frequent cleaning. The material's resistance to extreme temperatures and UV rays ensures the tank remains stable in varying weather conditions, enhancing its longevity.

fiberglass water tank. Their non-porous surface prevents algae growth, reducing the need for frequent cleaning. The material's resistance to extreme temperatures and UV rays ensures the tank remains stable in varying weather conditions, enhancing its longevity.  thread rock button bit. Unlike traditional flat-bottom bits, button bits feature protruding, dome-shaped buttons that enhance their penetration capabilities. The buttons, often made of tungsten carbide, are known for their hardness and resistance to wear, ensuring a longer lifespan for the bit.

thread rock button bit. Unlike traditional flat-bottom bits, button bits feature protruding, dome-shaped buttons that enhance their penetration capabilities. The buttons, often made of tungsten carbide, are known for their hardness and resistance to wear, ensuring a longer lifespan for the bit.  fiberglass trough cover. Their lightweight design allows for easy handling and placement, reducing labor costs and downtime. Additionally, their resistance to chemicals and weathering means they require minimal upkeep, translating into long-term cost savings.

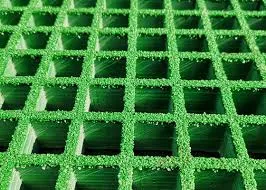

fiberglass trough cover. Their lightweight design allows for easy handling and placement, reducing labor costs and downtime. Additionally, their resistance to chemicals and weathering means they require minimal upkeep, translating into long-term cost savings. Molded fiberglass reinforced plastic (FRP) grating provides corrosion resistance in the most demanding environments. Manufactured by combining thermosetting resin with continuous fiberglass rovings in precision molds, each panel contains approximately 65% resin and 35% fiberglass rovings. This combination optimizes corrosion resistance, UV protection, and structural integrity.

With an extension rod, you can easily adjust the length of the drill bit to suit the specific requirements of the project With an extension rod, you can easily adjust the length of the drill bit to suit the specific requirements of the project

With an extension rod, you can easily adjust the length of the drill bit to suit the specific requirements of the project With an extension rod, you can easily adjust the length of the drill bit to suit the specific requirements of the project core drill bit extension rod. This flexibility enables you to tackle a wide range of drilling tasks with ease and efficiency.

core drill bit extension rod. This flexibility enables you to tackle a wide range of drilling tasks with ease and efficiency.

Some of the industries that benefit from using Fiberglass Grating include:

grp car body. The material can be molded into virtually any shape or size, allowing car manufacturers to create unique and innovative designs that stand out on the road. This design versatility gives car designers the freedom to experiment with new shapes and styles, leading to more visually appealing vehicles for consumers.

grp car body. The material can be molded into virtually any shape or size, allowing car manufacturers to create unique and innovative designs that stand out on the road. This design versatility gives car designers the freedom to experiment with new shapes and styles, leading to more visually appealing vehicles for consumers.

frp underground tank. These tanks can be customized to fit a wide range of applications, from storing potable water for a municipality to holding hazardous chemicals for an industrial facility. The tanks can be designed to meet specific size and capacity requirements, making them an excellent choice for a wide range of projects.

Fiberglass grating can be cut on-site according to the size that you need. Flexibility is especially useful in flooring materials as you often need to cut them to fit the project.

spiral rod. DNA, the blueprint of life, is a double spiral rod, with two strands intertwined like a twisted ladder. This structure, discovered by James Watson and Francis Crick, unlocked the secrets of genetic information storage and transfer.

spiral rod. DNA, the blueprint of life, is a double spiral rod, with two strands intertwined like a twisted ladder. This structure, discovered by James Watson and Francis Crick, unlocked the secrets of genetic information storage and transfer.